Intelligent Production Efficiency Enhancement Plan

Intelligent Production Efficiency Enhancement Plan - "Innovate for the Future"

1. Overview of the Plan

The "Innovate for the Future" plan aims to upgrade the production process of Haiyang Yaliqi Garment Co., Ltd. by introducing advanced intelligent technologies, in order to enhance production efficiency, reduce costs, improve product quality, and achieve sustainable development.

2. Strategic Goals

Short-term goal: Introduce basic intelligent equipment to achieve automation in key production processes.

Mid-term goal: Establish an intelligent production management system to achieve real-time monitoring and optimization of the production process.

Long-term goal: To create a fully intelligent production environment and achieve intelligent manufacturing and the standards of Industry 4.0.

3. Key Strategies

3.1 Introduction of Intelligent Equipment

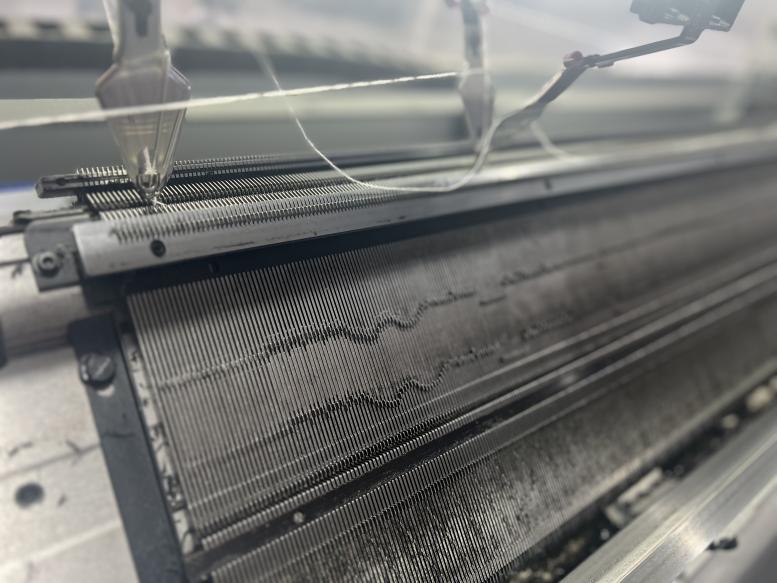

Detailed action: Evaluate and introduce intelligent production equipment such as automated sewing machines and intelligent cutting tables, reducing manual operations and enhancing production efficiency.

3.2 Optimization of Production Process

Detailed action: Through lean production methods, optimize the production layout and process, reduce waste, and enhance production efficiency.

3.3 Intelligent Production Management System

Detailed action: Develop or introduce a production management system to achieve automation and intelligence in order management, material management, and production scheduling.

3.4 Data Collection and Analysis

Detailed actions: Deploy sensors and data collection systems to collect production data, and utilize big data analysis techniques to continuously improve production efficiency and quality.

3.5 Artificial Intelligence and Machine Learning

Detailed action: Utilize artificial intelligence algorithms to achieve intelligent decision support in the production process, such as automatic scheduling and predictive maintenance.

3.6 Employee Training and Development

Detailed action: Provide employees with training on intelligent production, enhancing their ability to operate intelligent equipment and systems.

3.7 Supply Chain Collaboration

Detailed action: Achieve close collaboration with supply chain partners through an intelligent system, and optimize material supply and inventory management.

3.8 Environmental Friendliness and Energy Management

Detailed action: Implement an intelligent energy management system to monitor and optimize energy usage and reduce environmental impact.

4. Technical Support and Innovation

Detailed description: By leveraging cloud computing, Internet of Things (IoT), big data analysis and artificial intelligence technologies, an intelligent production infrastructure is constructed to enable data-driven decision-making.

5. Expected Outcomes and Impacts

Detailed description: Through the "Innovation for the Future" plan, it is expected to significantly enhance production efficiency, reduce production costs, shorten the time to market for products, improve product quality and enhance market competitiveness.

6. Implementation Steps and Timeline

Initial stage: Complete the selection and procurement of intelligent equipment and systems, and start with a small-scale pilot project.

Mid-term: Fully implement an intelligent production management system, carry out process optimization and employee training.

Later stage: Achieve full intelligence in the production process, continuously monitor and optimize production efficiency.

7. Risk Assessment and Mitigation

Detailed description: Establish a risk assessment mechanism to identify potential risks during the process of intelligent upgrade, formulate response strategies, and ensure the smooth implementation of the plan.

8. Continuous Improvement and Innovation

Detailed description: Establish a continuous improvement mechanism, encourage the team to explore new intelligent technologies and applications, and continuously optimize the production processes and systems.

Through the in-depth implementation of the "Innovate for the Future" plan, Haoyang City Yaliqi Garment Co., Ltd. will be able to establish an efficient, intelligent and environmentally friendly production system, providing a solid foundation for the long-term development of the enterprise and its competitiveness in the industry.